HELICORD AUTOMOTIVE V-RIBBED BELTS

HELICORD V-RIBBED BELT is the solution to the drive design problem faced by today's automobile engineers. With the ever increasing demands in vehicle engine design, the O.E. automotive engineer is expected to achieve higher efficiency, reliability, compactness and longer life of the automotive drive HELICORD V-RIBBED BELT with its multiple advantages offers the right choice to the automotive engineer.

HIGHER DRIVE EFFICIENCY

The multiple V-rib design of HELICORD V-RIBBED BELT provide more contact area than conventional V-belts. This in combination with the excellent flexibility of the V-Ribbed belt reduces transmission losses, towers heat build-up resulting in higher overall efficiency of the drive.

COMPACT DRIVE LAYOUT

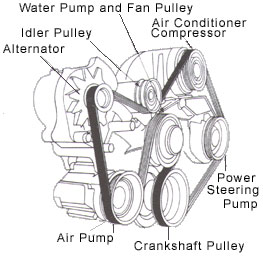

The greater tensile and contact area of HELICORD V-RIBBED BELT increases the power transmission capacity enabling O.E. automotive engineers to replace multi V-belt accessory drives with a single HELICORD V-RIBBED BELT. Moreover the back face of the belt is also used to drive an accessory. This unique feature enables HELICORD V-RIBBED BELT to be used in compact serpentine drives. The higher flexibility of HELICORD V-RIBBED BELT permits the use of smaller lighter pulleys ensuring optimum utilization of space and weight.

HIGH RELIABILITY AND LONG LIFE

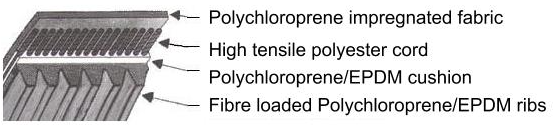

The use of high strength polyester cord, stringent quality control methods and choice of high quality raw materials, ensure high in-service reliability and longer service life of HELICORD V-RIBBED BELT in the high under bonnet temperatures of modern engines.